Coal is washed: clean coal is stored, waste is sent to shale stockpile, residual fine coal/waste slurry piped to sump for further treatment.

|

| Taff Merthyr Colliery raw coal treatment washing |

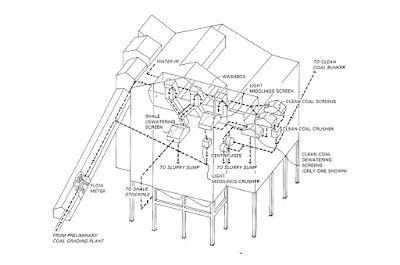

Coal and shale from the preparation stage are received in the raw coal treatment plant on AA303, passing over a flowmeter and at the end of the belt under an electromagnet to remove any remaining ferrous objects. Raw coal enters the washbox, in this case a Baum jig (plate 6), where it is mixed with clean water. In operation the washbox separates the material into four fractions, achieved by air pulsations and water flow, stratifying the coal in the jig in three separate stages. The heavier shale waste sinks and the lighter, clean coal rises, leaving two levels of coal and shale mix between - light middlings, largely coal with some shale, below which are heavy middlings, consisting mainly of shale with a little coal. Clean coal passes out through the end of the jig and three steel-bucket conveyors set at precise positions within the washbox remove the middlings and shale for further treatment, involving somewhat complex flows of material.

|

| Taff Merthyr Colliery raw coal treatment washing |

Clean coal

Clean coal passes by chute to the two clean-coal screens (plate 7) which separate material into three sizes: the overflow of between 50-125mm, a main flow of 12.5-50mm coal, and coal smaller than 12.5mm. The overflow is fed by chute into the clean-coal crusher for reduction to 50mm and is then tipped to AA312, so joining the main flow from the clean-coal screens to the clean-coal blending bunker for storage. Coal under 12.5mm passes to two clean-coal dewatering screens where water and solids smaller than 0.5mm are separated and piped to the slurry sump whilst the dryer coal 0.5-12.5mm passes to two centrifuges (plate 8). These dry the coal further but can be by-passed if necessary. Waste water passes to the slurry sump and dry coal is chuted to AA31 1 which transfers onto AA312 to the clean-coal blending bunker.

Light middlings

Middlings are drawn from the washbox between the heavy shale and the lighter coal and consist of a mixture of both. As the'name implies light middlings concentrate towards the upper part of the washbox tank and are comprised mainly of coal. The middlings are collected in an endless steel-bucket elevator and passed by chute to a screen; the chute can divert the elevator output directly to the clean-coal screens if required. Overflow from the light middlings screen of material larger than 12.5mm is chuted to the middlings crusher, reduced to 12.5mm then by scraper conveyor AA328 returned to the main washbox input on AA303, whilst the output from the screen under 12.5mm is piped to the clean-coal dewatering screens.

Heavy middlings and shale

Heavy middlings, consisting mainly of shale with some coal, are suspended in the lower part of the washbox. Formerly, these were processed separately but the heavy middlings screen and associated equipment have been taken out of use. The material is treated as shale; both are removed from the washbox by endless steel-bucket elevators (plate 9) and pass down chutes to the shale dewatering screen (plate 10). Solid matter over 0.5mm is chuted to the 'rubbish belt', actually four separate conveyors, which carries waste to the shale stockpile, whilst all material under 0.5mm and waste water is piped to the slurry sump.

|

| Taff Merthyr Colliery clean coal washing |

Taff Merthyr Colliery Process Recording Links:

1. Raising coal and stone extraction

2. Preliminary coal grading

3. Raw coal treatment (washing)

4. Fines separation

5. Preparation of treated coal for market

6. Shale disposal and reclamation of surface water

7. Identification of principal surface features

This article on Taff Merthyr Colliery has been divided into 7 separate issues, to catch next week's instalment on 'Fines separation' consider subscribing to the Heritage of Wales News Feed by e-mail, and have the next issue sent directly to your inbox. An alternative way is by the full feed RSS, just click this

RRS button to view subscription options!

RRS button to view subscription options!

1 comments:

Be among the first to comment on 'Raw Coal Treatment (Washing)'.

Stay up to date with the latest information from 'Heritage of Wales News' by entering your e-mail (top right), to receive regular updates.

Post a Comment

www.rcahmw.gov.uk

Please comment and let us know your views or your news. Remember that what you write can be read by everyone. RCAHMW reserves the right not to publish offensive or inaccurate material.